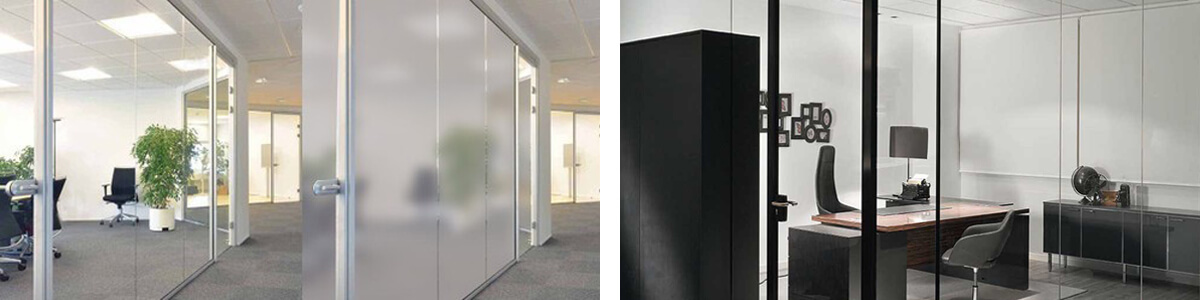

Switchable PDLC film and smart glass are an unstoppable revolution in the glass industry, and the use of architects, homeowners, and builders is constantly escalating. They enjoy the benefits of privacy, security, energy-saving, and ease of installation. Just by using the remote control, the switchable glass film changes from transparent to opaque.

Procedures to Installation of switchable PDLC film / Glass:

Step1: Connect Bus bar to Switchable Film

Broadly speaking, a bus bar is a type of conductive rod, bar or strip.

In contrast to smart films, bus bars are a type of conductive copper tape that is affixed to one or both edges of a PDLC film before being laminated between two pieces of glass.

The copper strip acts as a conduit for a step-down (48 / 60V AC) current, which activates the liquid crystal in the film. The current is diffused through a conductive indium tin oxide coating on the surface of the surrounding PET film.

Some Smart Film panels may require multiple bus bars to ensure a complete and even distribution of current.

Double strand

Wires are soldered to either end of each bus. They are double (or double) wires. This apparent “dual-effect” is to compensate when the wires come off or come off during panel installation. Depending on your requirements, busbars can be applied to the long or short sides.

Depending on their proportions, some panels may require two bus bars.

Acceptable locations of bus bars on smart film panels.

Step2: Tools Preparation

- Nitrile gloves (or other non-powdered, lint-free gloves)

- Glass cleaner (non-ammonia based)

- Silicone adhesive sealant

- Applicator squeegee/Glass scraper

- Rubber Roller

- Lint free cloth (microfiber)

- Low adhesive tape (painters tape)

- Packaging tape

- Wire mold / trim

- Ladder (if necessary)

- Electrical tester (switch cord)

- Soldering iron

- Electrical wire leads

Inspect each piece of the film immediately, without wrong sizes, damaged edges and then proceed installation.

Step3: Cleaning window or door existing glass

Use a window scraper or blade to remove and dirt/blemishes from the glass surface. Repeat it without any dirt/blemishes. And then Spray the glass with glass cleaner and clean with a absorbent cloth to completely clean and dry. Then Using a lint-free cloth, wipe the glass surface until it is dust-free.

Step4: Cleaning the switchable PDLC film

Using a lint-free cloth, wipe down the protective liner on the cling side of the film to remove any dust.

Step5: The size of tearing the covered film

Put on clean nitrile protective gloves and using the edge tab of the label to remove the first 100mm(4″) of the protective liner covering the cling side. Make sure that dust does not fall onto the cling Sid

Step6: Sticking film

Align the edge of the Film with the top edge of the glass. When in position, run your finger along to press down and fix the top edge(the adhesive strip will hold the film in position).e.

Step7: Sticking cautions

Gradually pull away from the protective liner and allow Film to slowly adhere to the glass surface under its own pressure. Using the soft edge squeegee move down Film working in horizontal lines left to right to disperse any air bubbles. If any small bubbles are still visible, carefully lift the film and let it sit back down under its own pressure. If any small bubbles are visible, carefully check for any dust particles. If so, use adhesive tap and carefully remove the dust particles. Otherwise, carefully lift Film and let it sit back down under its own pressure (while using the squeegee).

Repeat the above process until you have a bubble-free installation (for bubbles near the edges).

Step8: Soldering and circuit connection

Once the Film is in place, connect the Clips-On electrode to the transformer. For best results, use cable guides along the edge of the window.

Step9: Testing

Connect the transformer to the power source and test Film(switching from opaque to clear).

Step10: Silicone sealant of the edge

For additional security or when using film in a high moisture environment use non-acidic based silicone(e.g. GE-83)along the edges of the film about 5mm, when it dries(about 3 days) later to power on and use the switchable film.

Step11: With 3M glue to seal the edge

Notice:

1. No water using in installation unless for clean the glass.

2. The needed film size is 2-3mm less than the glass size to fit installation.

3. All should be done under a dust-free working environment.

4. Remember to use silicone sealant glue.