Smart Glass

According to the similarities and differences in control methods and principles, Smart Glass can be electrically controlled, temperature controlled, light controlled, pressure controlled, and so on, to achieve the switch between transparent and opaque state of the glass. Due to various conditions, the mass production of Smart Glass on the market, almost all of them are electronically controlled Smart Glass.

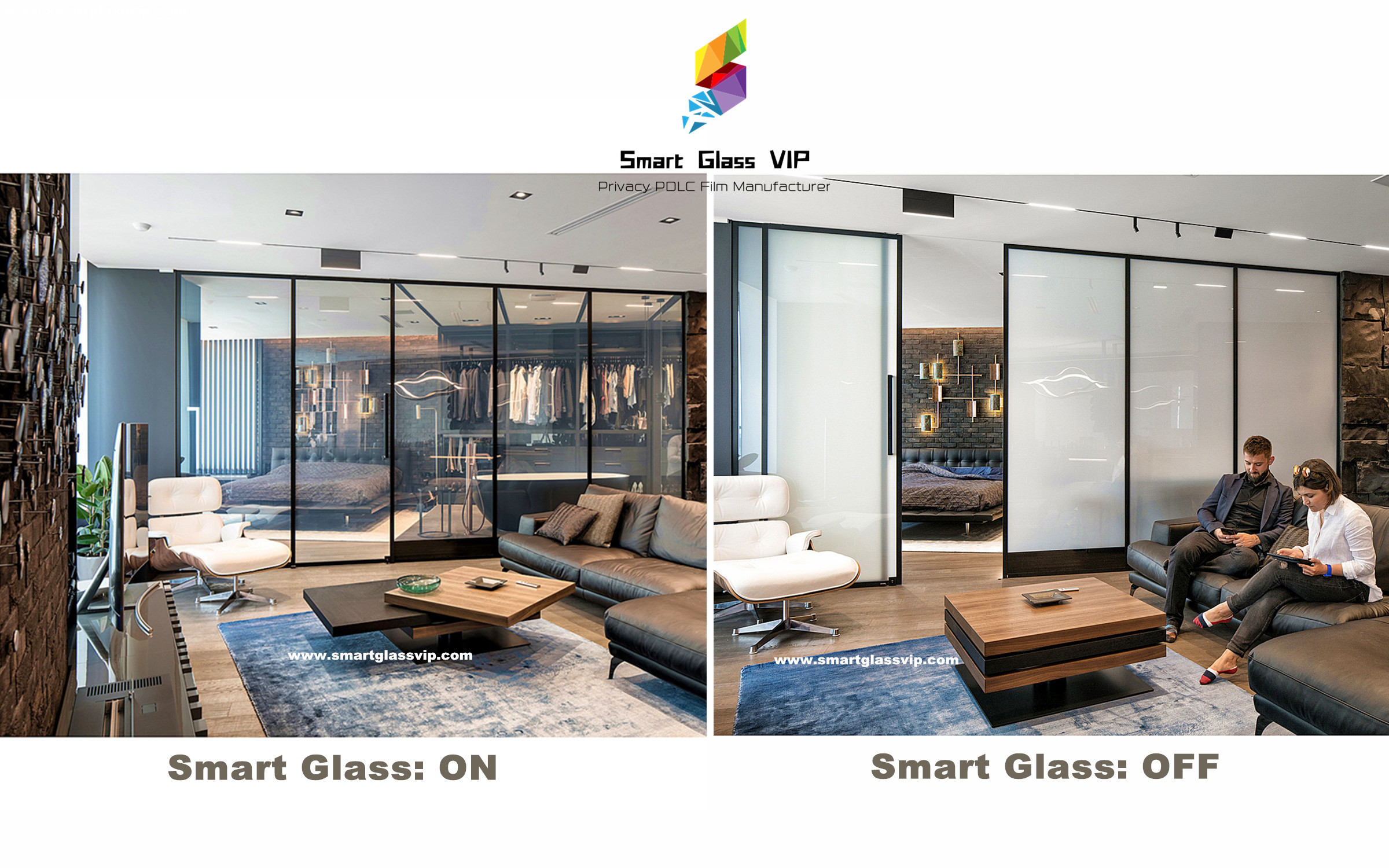

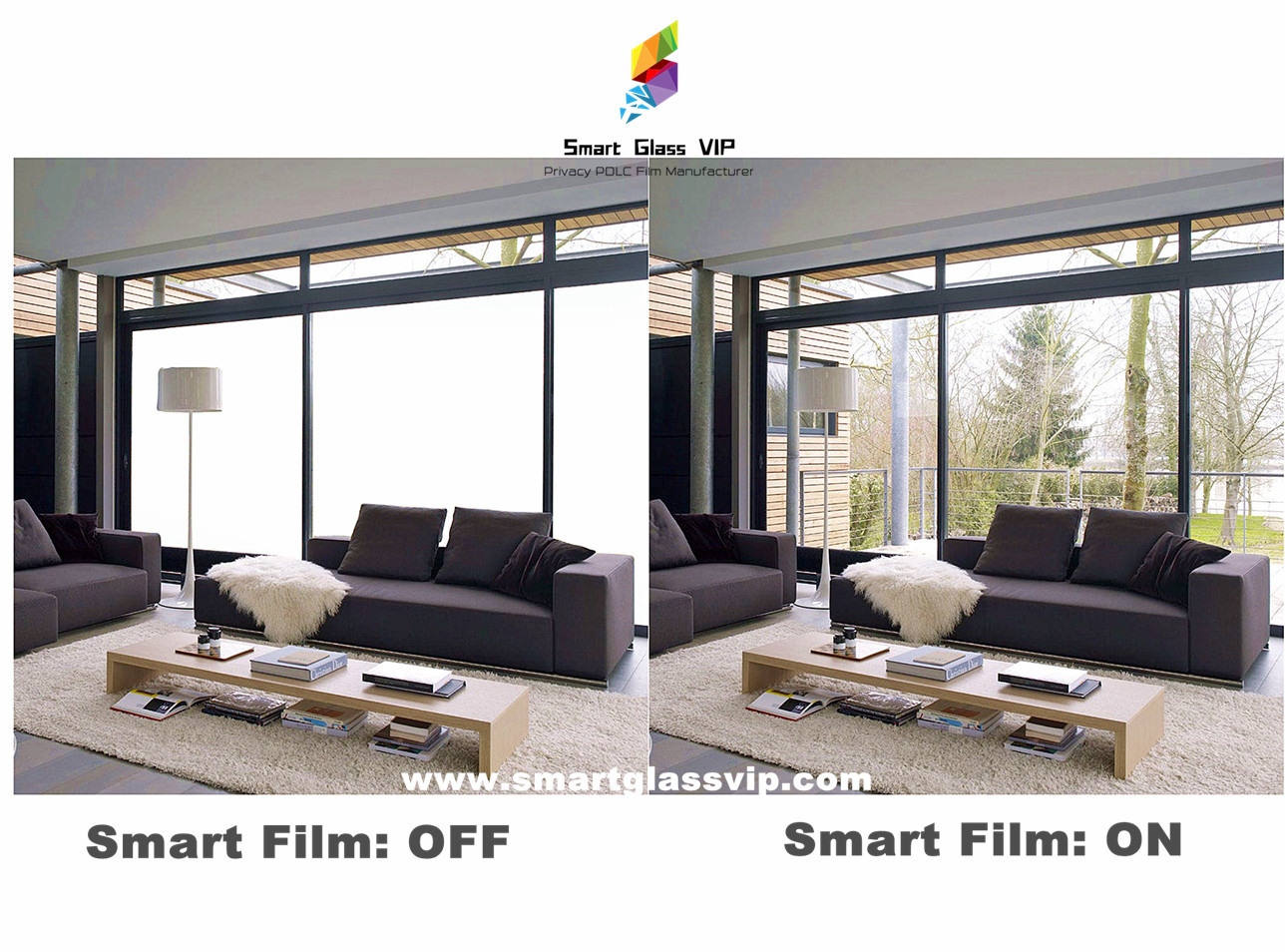

The principle of electronic Smart Glass is relatively easy to understand: when the power off the electronically controlled products, the liquid crystal molecules inside the electronic Smart Glass will show irregular dispersion state, so that light can not enter, so that the electronic glass presents an opaque appearance.

Product definition

Smart Glass is a new type of special photoelectric glass product that combines liquid crystal film into the middle of two layers of glass, and after high temperature and high pressure gluing, it is integrally formed into a sandwich structure. The user controls the transparent and opaque state of the glass by controlling the current on and off. The glass itself not only has all the characteristics of safety glass, but also has the privacy protection function of controlling whether the glass is transparent or not, due to the characteristics of the liquid crystal film interlayer, Smart Glass can also be used as a projection screen, instead of ordinary curtains, presenting high-definition images on the glass.

Working Principle

When the Smart Glass off the power, the liquid crystal molecules inside the electronically controlled Smart Glass will show irregular dispersion state, this time the electronically controlled glass presents the appearance of translucent and opaque state; When the Smart Glass is energized, the liquid crystal molecules inside the neat arrangement, the light can freely penetrate, this time the Smart Glass instantly presents transparent state.

control method

Artificial opening, artificial dimming, light control dimming, voice control opening, temperature control opening, remote switch, remote network control, can be combined according to customer requirements.

Detailed specification

Name: Switchable Glass,Privacy Glass, Smart Glass ,PDLC Glass,Magic Glass.

Invention time: late 1980s

Technical Category: PDLC

Panel options: ordinary float glass, super white glass, colored glass, etc. (Tempered glass is not recommended).

Glass thickness: ranging from 5.5mm-40.5mm. (2+2-19+19)

Jacket thickness: 1.5mm

Drilling and trenching: yes

Storage temperature: -20°C to +60°C.

Operating temperature: -10°C to +50°C

Operating voltage: 24VAC, 48VAC or 65VAC (non-safe voltage above 65VAC is not recommended)

Light transmittance: about 81-87%

Privacy distance: Shields any image 3cm away from the other side of the glass.

Viewing angle: approximately 140 degrees.

Average energy consumption: 5 watts per square meter.

Normal life: around 15 years

History of Development

Smart Glass was invented by researchers at Kent State University in the late 1980s and applied for invention patents. In China, people used to call the Smart Glass as intelligent electric Smart Glass, intelligent glass, liquid crystal glass, electric glass, color changing glass, PDLC glass, Smart glass, magic glass and other names.

Smart electric Smart Glass began in 2003 in the international market widely used. Due to the high price and few people know about it, the development in China was slow in the last decade. With the continuous rapid growth of the national economy and the rapid development of the building materials market, intelligent electronically controlled Smart Glass has gradually been accepted by the construction and design industry and began to be used on a large scale, with the further reduction in cost and market price, Smart Glass has also begun to enter the home decoration applications, it is believed that in the near future, this practical high-tech products will enter thousands of households.

Product Process

Smart Smart Glass is a laminated glass with a liquid crystal film (commonly known as Smart Film, LCD film) sandwiched between two layers of glass, the liquid crystal film is covered by an EN film in the center and is formed in a one-step oven at high temperature. The liquid crystal film is covered by the EN film in the center, and it is formed in a one-step high temperature oven.

Several processing and production methods for Smart Glass are explained in detail.

1、One-step vacuum forming method. Its equipment structure is simple, but only a few of the equipment can really make Smart Glass, its processing process seems simple, but in the actual operation of the process of temperature control precision requirements are very high, there will be a waste of the phenomenon of bubbles, gum, haze. Due to the high cost of production of Smart Glass, tolerate no more than one percent of the processing waste rate, so non-standard enterprises and the technical ability to reach the precise control of enterprises, generally do not dare to use this method of production of Smart Glass. Very few domestic manufacturers to grasp the essence of the “one-step” Smart Glass processing. However, this method to make the Smart Glass finished product has a long service life and relatively stable performance.

2、Use autoclave processing. Autoclave processing of the former process is actually similar to the one-step process, only later with the autoclave high pressure and high temperature molding. Autoclave processing can effectively avoid bubbles, gumming and other phenomena, but the shortcomings are obvious, due to the pressure of the autoclave forming glass to withstand two times more than the one-step vacuum forming, while the main interlayer material of the Smart Glass conductive film will be caused by the large shrinkage rate of the conductive coating fracture or increase the resistivity, so that the performance and service life of the Smart Glass products is greatly shortened.

Autoclave molding method for Smart Glass equipment must be dedicated, accurate and suitable for the characteristics of Smart Glass, unfortunately, very few domestic manufacturers are dedicated, most are mixed with conventional laminated glass, autoclave frequent parameter adjustment can not guarantee the parameters of the Smart Glass requirements, but also easy to damage equipment.

3, the water bath method is to immerse the sealed fixture in a 100-degree water bath, is the most accurate and uniform temperature of the various processing techniques, but the fixture is very difficult to manufacture, only the Japanese manufacturers.

Applications

Product Performance

1. privacy protection function: the biggest function of intelligent Smart Glass is privacy protection function, you can control the glass at any time.

The transparent opaque state of the projector.

(2) Projection function: intelligent Smart Glass is also a very good projection hard screen, in the right light environment, if you choose a high lumen projector, the projection imaging effect is very clear and outstanding. (It is recommended to choose rear projection imaging method)

(3) Have the advantages of safety glass, including the safety performance to prevent splattering after rupture, good impact strength.

(4) Environmental protection characteristics: the dimming film and film in the middle of the Smart Glass can be insulated, blocking more than 99% of the ultraviolet and 98% of the infrared. Shielding part of the infrared to reduce thermal radiation and transmission. And shield ultraviolet radiation, can protect indoor furnishings from ultraviolet radiation and fading, aging, etc., to protect personnel from direct ultraviolet radiation and diseases caused by.

5 sound insulation properties: the dimming film and film in the middle of the Smart Glass has a sound dampening effect. Can partially block the noise.

Practical use

Smart Glass, as you can literally see, is a type of glass that has the property of being able to adjust the state of light transmission or opaque. So what is the principle of glass dimming? Is it the intensity of the light or the transparency that is being regulated? Let’s take a look at its technical definition first. Smart Glass belongs to special glass for architectural decoration, also known as electronic curtain. This is a product based on film technology, liquid crystal molecules attached to the ITO substrate, the electrode at the edge of the light transmission to introduce electric current, through the power supply to change the arrangement of liquid crystal molecules, and then control the transparency of the glass or not. Smart Glass can freely switch the permeability of the space, is a remote control of the curtain, privacy protection, at your disposal. As a technological product, what applications can Smart Glass be used in? Here is a brief summary for you.

Business Applications

Example 1: The role of a projection screen. In this case, Smart Glass has another commercial name, “smart glass projection screen”, which means that it can be used to display background decorative pictures when transparent, or as a glass wall in a conference room. The opaque state can replace the imaging curtain, and has a clearer picture. In this way, it breaks the monopoly of the traditional concrete wall and achieves multiple functions.

Example 2: Partitioning of office areas, meeting rooms and monitoring rooms. Even a large office area separated by several walls or frosted glass will look small and stuffy, and all the transparent glass design and lack of business confidentiality, then you really need a transparent glass material that can adjust the light intensity to solve the problem. A complete blur in the peripheral gaze.

Residential Applications

Example 1: Exterior settings. Adding Smart Glass to balcony windows can make a revolutionary improvement on the poor privacy of buildings where everyone can see. Under daily condition, adjust the window to transparent state to keep the light translucent; under casual condition, adjust the window to opaque state to maintain the sense of security, but still have sunlight close to you, killing two birds with one stone.

Example 2: Indoor space partition. The use of Smart Glass to separate rooms, improve the layout of space, increase the freedom of light adjustment and ensure the privacy of different areas will get unexpected results.

Example 3: Used as a small home theater curtain, effectively combining the curtain and screen. (Same principle as business projection curtain)

Example 4, under the premise of choosing safe voltage, the Smart Glass is used as a bathroom and toilet partition, which not only makes the layout bright, but also protects privacy well.

Application of medical institutions

It can replace the curtain, play the function of partition and privacy protection, solid and safe, sound insulation and elimination of impurities, but also has the benefit of environmental protection and cleaning and not easy to pollute, removing the worries and psychological pressure for medical workers and patients.

Museums, exhibition halls, shopping malls, bank security applications

It is recommended to be used in the window, counter bulletproof glass and showcase glass of shopping malls, banks, jewelry stores, museums and exhibition halls. It remains transparent during normal business application, and in the event of an emergency, it can be remotely controlled to instantly reach a blurred state, making criminals lose their targets and ensuring maximum personal and property safety.

In short, the application of Smart Glass is very wide, covering administrative offices, public services, business entertainment, home life, advertising and media, exhibition and display, imaging, public safety and many other fields.

Selection Guide

Although the price of Smart Glass from the introduction of the first ten thousand U.S. dollars per square meter down to a few thousand yuan per square meter, but due to high costs and other reasons, the price of Smart Glass has been relatively speaking is still at a high level, which also determines its application areas more positioned in the high-end market. Of course, with the further maturation of the market and further deepening of customer understanding of this product, the application of Smart Glass has become increasingly widespread, has stepped out of the application framework of the building materials field, in-depth application of household appliances, glass panels and other applications, the development potential is huge.

Because of the price relationship, Smart Glass into the mainland Chinese market late, with the growing prosperity of the Chinese economy, Smart Glass in China has been rapid development. Domestic Smart Glass market brand mountain, just like entering the warring states era. On the market Smart Glass business marketing methods are diverse, product quality is also uneven and uneven. Therefore, when buying Smart Glass, you should have some professional knowledge to carefully identify the quality of authenticity, so as not to pursue the latest trend but spend a lot of money to buy a shoddy product, when the wrong person.

Check technical parameters

Customers with strict quality requirements, it is necessary to do a more detailed understanding of the technology of Smart Glass.

a. Good quality Smart Glass when the light transmittance is extremely good, clear and transparent, beautiful appearance and power off when the light transmittance but not transparent, can be extremely good protection of privacy. Simple test method: put the palm of the hand on the back of the glass, power off state, from the front to look at the back of the palm, although the visible blurred back, but must not see the fingerprints of the palm. Or put an object on the front glass according to 3cm, in the two sides of the light balance and non-side backlight, one side of the strong light, from the opposite side of the case, should not see the object is better. Better quality Smart Glass transmittance should be about 75%.

PVB (polyvinyl butyral) has been used as interlayer for more than 30 years, PVB contains hydroxyl group which has strong water solubility and is more sensitive to humidity, and PVB consumes more energy. EVA (polyethylene vinyl acetate) is the most widely used material in the world. As an interlayer, PVB interlayer has been gradually replaced with vinyl acetate (VAE), which can avoid the above problems and has better transmittance.

c. Consumers can choose the corresponding glass panel according to the functional requirements of the application areas of glass. General manufacturers or new manufacturers, most of them will recommend the use of tempered glass as the substrate of the Smart Glass, but the transparency and flatness of tempered glass is not as good as float glass, due to the different tensile force, will lead to the phenomenon of Smart Glass open gum and delamination.

d. Smart Glass in the installation of the choice, should be selected with a professional installation team of the manufacturer to install, for the need to hang the installation, try to avoid perforation, due to perforation in the Smart Glass, will change the order of the molecules within the liquid crystal film, resulting in the Smart Glass in the process of burning. Domestic manufacturers have mastered the advanced borderless hanging hanging method, effectively solve the problem of Smart Glass hanging installation of perforation.

Quality of Smart Film

The quality of the dimming film is one of the most important factors in determining the quality of the finished product of Smart Glass. Therefore, when buying Smart Glass, you should check the quality of the dimming film from Smart Glass manufacturers.

Liquid crystal film was first invented by Chinese in America and later developed to Japan, Korea, Taiwan and other countries and regions. Due to technical limitations, the width of LCD film was limited to 1.8 wide and length 3.3, but due to market demand, the mainstream international manufacturers who have mastered the core technology have continuously upgraded their products, taking the mainland China market as an example.

Between 1990 and the fourth quarter of 2004, the largest size of Smart Glass that engineers could buy on the market was a Japanese product that was expensive to import (10,000 yuan per square meter) and only 980 mm wide.

By the second quarter of 2006, both Korean and Chinese products were available in widths up to 1200mm at half the price.

In the fourth quarter of 2008, the United States began selling its latest generation of products in China, up to a maximum width of 1600mm, with other major international manufacturers following suit.

In the fourth quarter of 2010, at the Glasstec 2010 in Germany, China’s Smart Glass, equivalent to the latest fourth generation, was presented in widths of up to 1850mm (1800mm as standard).

Check project examples

To purchase Smart Glass products with stable performance and guaranteed after-sales service, the most important thing is to look at the relevant application engineering cases of the manufacturer. When choosing manufacturers, we should not only look at the actual engineering cases of the manufacturer, it is best to carefully check the real photos of the actual installation site of the manufacturer’s Smart Glass, rather than the effect of PS after the computer. Therefore, before buying Smart Glass, you can ask the manufacturer to provide several well-known projects and the site of the real photos for reference.